Lean Six Sigma Standard Work: The Ultimate Guide to Sustainable Process Excellence

Introduction

Speed, quality, and repeatability form the holy trinity of world-class operations. Lean Six Sigma standard work is the discipline that unites them: it documents the single best-known method for performing a task, so every operator, analyst, or nurse can achieve takt time with minimal variation. When standard work is treated as a living contract—audited daily and improved continuously—it becomes the foundation for breakthrough performance and a learning culture. Understanding Lean Six Sigma standard work is essential for optimizing processes.

Incorporating Lean Six Sigma standard work ensures that all processes are aligned with best practices, allowing for greater efficiency and quality assurance. The principles of Lean Six Sigma standard work are essential for any organization striving for excellence. Standard work and continuous improvement should be viewed as a constant, ongoing process, where enhancements are integrated into daily operations.

Table of Contents

The information on this site is free. However, we partner with companies that offer products that help our readers achieve their goals. This site contains affiliate links, and we may get commissions for purchases made through links and ads to support this site at no additional cost to you. Please read my disclosure for more information.

Understanding the DNA of Lean, Six Sigma, and Standard Work

The Birth of Lean Thinking

In post-war Japan, Toyota engineers Taiichi Ohno and Shigeo Shingo faced chronic shortages of cash, space, and materials. Their answer was the Toyota Production System (TPS)—a management philosophy that synchronizes every activity to real customer demand, eliminates the seven classic forms of waste (muda), and empowers any worker to stop the line when a defect appears (jidoka). Kanban cards, SMED (quick changeover), and heijunka (level scheduling) were not invented as isolated tools; they were practical responses to achieving quality at a low cost. These foundational lean tools are utilized to optimize workflows and eliminate waste, thereby supporting continuous improvement in lean manufacturing. Over the next five decades, TPS demonstrated that small, repeated improvements compound more rapidly than sporadic “big bang” projects, inspiring the broader lean manufacturing movement.

Six Sigma’s Data-Driven Evolution

By the mid-1980s, Motorola was incurring millions of dollars in rework costs. Engineer Bill Smith quantified the cost of defects in “defects per million opportunities” (DPMO). He set an audacious stretch goal: fewer than 3.4 defects per million, equivalent to six standard deviations between the process mean and the nearest specification limit. The structured DMAIC roadmap—Define, Measure, Analyze, Improve, Control—provided teams with a step-by-step approach to identifying root causes using statistics rather than trial and error. GE, Honeywell, and 3M soon adopted the approach, proving the financial payoff in both manufacturing and service settings. Today, Six Sigma remains the most widely used data framework for reducing variation and establishing best practices.

Sigma Green Belt certification equips professionals with the skills to implement Six Sigma methodologies and drive process improvement using best practices.

Lean Six Sigma standard work helps to streamline operations by ensuring that each task is well-defined and optimized.

Why Lean Six Sigma Standard Work Is the Glue

Lean eliminates waste; Six Sigma attacks variation. Standard work glues them together by recording the safest, fastest, and easiest sequence to perform every task. At Toyota, a standard work sheet always contains three elements:

- Takt time—the heartbeat set by customer demand.

- Work sequence—the exact order of steps, motions, and checks.

- Standard in-process inventory—the minimum materials needed to maintain a steady flow. Because the sheet is visual, every operator can see abnormal conditions the moment they arise, and every improvement event starts by comparing reality to the documented baseline.

Standard work is a practice that should be regularly reviewed and improved through ongoing efforts.

Key Principles Behind Lean Six Sigma Standard Work

Implementing Lean Six Sigma standard work can significantly enhance productivity and employee satisfaction.

Takt Time, Cycle Time, and Work Balance

- Takt time converts daily demand into a pace: available production minutes divided by the required units.

- Cycle time is what the process achieves per unit.

- Target time serves as a benchmark for performance, enabling teams to compare actual work durations against established standards and ensure that production goals are met.

- Work balance ensures no team member is idle while another is overloaded.

Visual balance charts and Yamazumi boards make these relationships obvious; when the cycle exceeds takt, a kaizen team strips out waste, rebalances tasks, or introduces automation to restore the flow.

Voice of the Customer (VOC) Integration

Defects that customers never notice are irrelevant; those they perceive as ruining loyalty are significant. Lean Six Sigma standard work begins with VOC research, which comprises interviews, NPS surveys, and gemba observations, to translate customer language into measurable CTQs (critical-to-quality characteristics). Every inspection point, error-proofing device, and job aid on the sheet is there to protect a key element of critical to quality (CTQ).

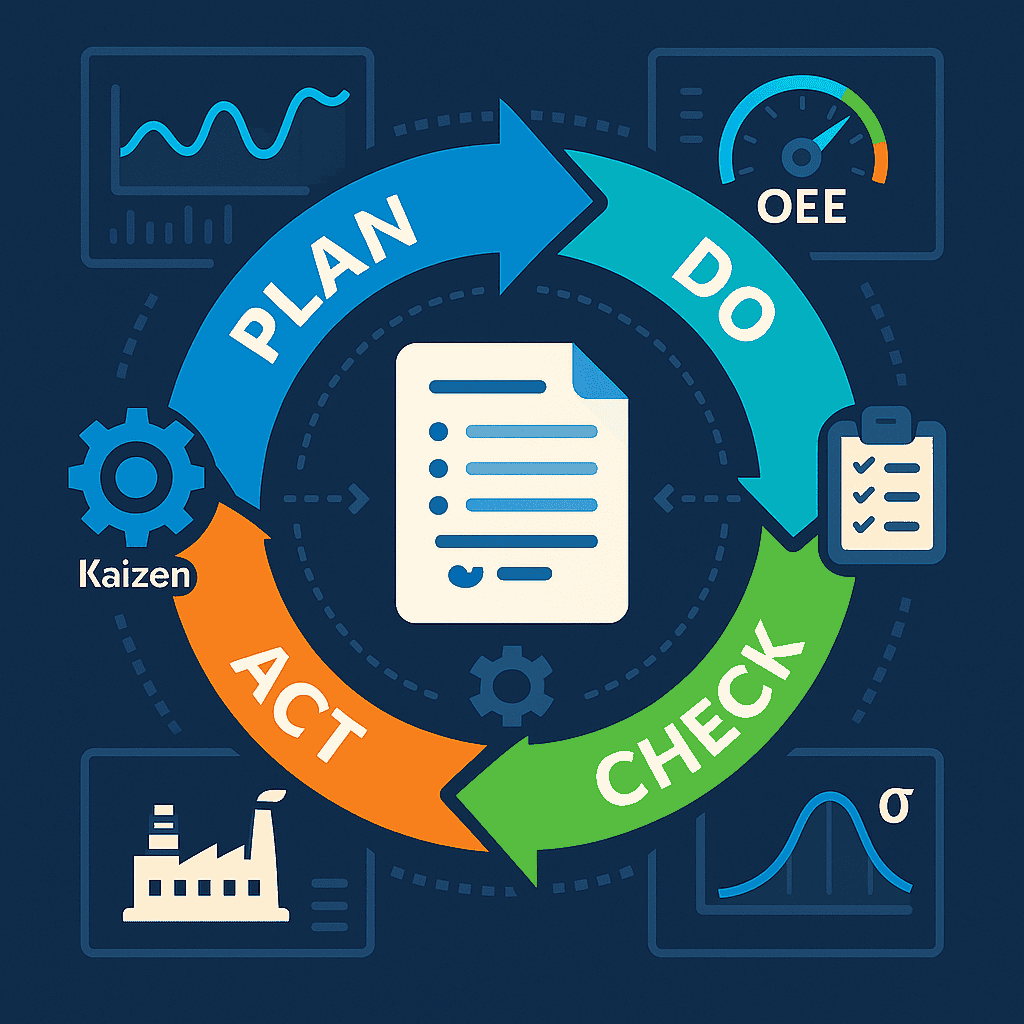

PDCA and DMAIC Synergy

On a mature production line, supervisors run Plan-Do-Check-Act micro-cycles daily to tweak ergonomics and sequence. When problems resist quick fixes, a cross-functional Green Belt launches a complete DMAIC project to identify opportunities for improvement. Both streams feed into the same standard work document, preventing the “parallel universe” syndrome where kaizen gains and Six Sigma gains compete rather than reinforce each other.

Both PDCA and DMAIC approaches often identify quick wins that can be implemented rapidly to boost team morale and demonstrate early success.

Step-by-Step Blueprint for Designing Standard Work

Process Mapping and Gemba Walks

Grab a pencil, a stopwatch, and an open mind. Walk the gemba, sketch the value stream, and record every queue, motion, and hand-off. The goal is not to audit people, but to expose friction points—such as extra clicks on an ERP screen, awkward reaches on an assembly cell, or triple handling of lab samples. Mapping grounds the team in facts instead of opinions.

Process mapping also helps teams capture current best practices and ensure they are consistently followed.

Time Studies and Work Elements

Next, break down jobs into work elements no longer than two or three seconds each. It takes at least ten cycles to capture the variation range. A spaghetti diagram of operator footsteps often reveals 30% “walking waste” that nobody had noticed. These data become the raw ingredients for line balancing and later Six Sigma statistical tests.

Defining the Best-Known Method (BKM)

With waste identified and critical steps isolated, the team experiments with different sequences until it finds the combination that delivers quality at takt with the least ergonomic strain. This BKM is now frozen—“the best we know today”—and logged onto the standard worksheet to ensure maximum efficiency. Importantly, it is expected to change whenever a better idea surfaces.

When new procedures are developed, they should be integrated into the standard work documentation to ensure consistency and uniformity.

Visual Work Instructions and Job Aids

Written prose alone cannot convey motion. Convert the BKM into one-point lessons with photos, short clips, or augmented-reality overlays so a new operator can master the task in minutes, not days. Color-coded checkpoints and drawing call-outs reduce reliance on tribal memory and language proficiency. Visual work instructions should also clearly list the materials required for each task to prevent errors and delays.

Implementing Lean Six Sigma Standard Work on the Shop Floor

Training Within Industry (TWI) Methods

During World War II, the U.S. War Manpower Commission created TWI to teach thousands of inexperienced workers in record time. TWI methods are particularly effective for onboarding new employees and ensuring they quickly learn and apply standardized procedures. The Job Instruction (JI) module remains the gold standard: demonstrate the job at full speed, break it down step-by-step, explain key points and reasons, then have the learner perform while coaching. In ten focused minutes, the employees gain competence and respect for the standard.

Layered Process Audits (LPAs)

As a final note, Lean Six Sigma standard work remains a key component of operational excellence.

Compliance breaks down when leaders disregard the standard. LPAs address this by assigning short, frequent audits at multiple levels—operator self-checks are conducted every hour, supervisor audits occur at the end of each shift, and manager audits are performed weekly. Audit questions are binary and focused on process steps and critical to quality attributes (CTQs): “Is the torque gun set to 12 Nm? Y/N.” These layered process audits include regular quality checks to ensure consistent output and minimize errors. Because each layer inspects the previous one, gaps surface quickly without blame. Plants that adopt LPAs often see double-digit reductions in customer complaints within six months.

Training within industry emphasizes the role of Lean Six Sigma standard work in effective onboarding.

Leader Standard Work and Daily Accountability

Effective training in Lean Six Sigma standard work will prepare employees for the demands of their roles.

Adopting Lean Six Sigma standard work practices encourages accountability and transparency within teams.

Front-line leaders carry notebooks listing daily gemba walk routes, tier-meeting checkpoints, and problem-solving coaching sessions. These routines turn management from a reactive fire brigade into a proactive support system. When leaders live by their lean principles and standards, operators trust continuous improvement as more than a slogan.

Leader standard work and daily accountability also contribute to increased productivity by maintaining focus on process improvements.

Leaders must support the implementation of Lean Six Sigma standard work to foster a culture of improvement.

Green Belt Certification and Standard Work

Lean Six Sigma standard work helps organizations remain competitive in a rapidly changing marketplace.

Green Belt certification is a pivotal step for professionals seeking to drive Lean Six Sigma initiatives within their organizations. As a Green Belt, individuals gain a deep understanding of how to identify opportunities for improvement and implement standardized work, a key element in achieving operational excellence. Standardized work forms the backbone of Lean manufacturing, ensuring that every process is performed consistently and efficiently, aligning with customer demand.

During Green Belt training, participants learn to break down processes into defined steps, analyze cycle times, and establish the optimal process layout to support smooth operation. By documenting the best-known method for each task, Green Belts help organizations maintain standard inventory levels and eliminate unnecessary variation, which is essential for meeting customer demand and improving overall process layout.

Green Belts are also equipped to lead teams in identifying inefficiencies and implementing improvements that enhance quality and efficiency. Their expertise in Lean Six Sigma principles enables them to standardize processes, monitor performance, and drive continuous improvement across the organization. Ultimately, Green Belt certification empowers professionals to embed standardized work as a core element of Lean Six Sigma, ensuring that processes remain efficient, repeatable, and capable of delivering consistent quality.

Lean Six Sigma standard work is foundational for achieving sustained performance improvements in organizations.

Green Belt training emphasizes the importance of Lean Six Sigma standard work in improving process efficiency.

Sustaining Gains Through Continuous-Improvement Loops

Kaizen Events and Rapid Improvement Workshops

To truly leverage the benefits of Lean Six Sigma standard work, organizations must embrace a culture of continuous improvement.

A kaizen event targets a stubborn bottleneck—say, a 90-second screen printing step in an otherwise 45-second line. Within three to five days, the team dissects root causes, trials countermeasures, and updates standard work before presenting the results. A 30-60-90-day audit ensures that gains are sustained and that adjacent processes were not compromised.

Statistical Process Control (SPC) for Ongoing Monitoring

Control charts transform raw production data into early-warning radar. If the upper control limit is breached, the operator triggers an Andon, investigates the issue, and either corrects it or escalates the problem to the next level. Because control limits are based on actual process capability, they prevent both over-reacting to common-cause noise and under-reacting to special-cause spikes.

Learning from case studies of Lean Six Sigma standard work implementation can provide valuable insights.

Leveraging Digital Gemba and IIoT Dashboards

IIoT sensors stream cycle time, temperature, vibration, and energy use to cloud dashboards visible at every tier meeting. When takt-time adherence slips, supervisors can click the data trail and view a short video clip from the workstation to diagnose the cause, all within minutes.

Different industries can adapt the Lean Six Sigma standard work to their specific operational needs.

Case Studies: Real-World Wins with Lean Six Sigma Standard Work

By sharing best practices in Lean Six Sigma standard work, organizations can enhance their overall efficiency.

Industry | Challenge | Lean Six Sigma Solution | Result |

|---|---|---|---|

Automotive Assembly | 15-minute robot change-overs throttle throughput | SMED kaizen, TWI retraining, digital standard work sheets | 40 % cycle-time reduction and 18 % OEE uplift |

Healthcare – Hospital Pharmacy | 6-in-1000 medication errors risked patient safety | DMAIC study, e-SOP rollout, layered audits | 60 % drop in errors and $2 M annual savings |

Financial Services | Mortgage approvals averaged 28 days | Value-stream map, queue caps, e-standard work, visual SLA dashboards | 25 % faster approvals and a 15-point NPS jump |

Embracing Lean Six Sigma standard work across various sectors leads to improved customer satisfaction.

Recognizing the significance of Lean Six Sigma standard work can drive innovation within organizations.

Each win followed the same pattern: map the process, stabilize it with standard work, and then push capability to world-class through Six Sigma analytics.

Standard Work in Different Industries

Standardized work is a powerful tool that transcends industry boundaries, enabling organizations across diverse sectors to achieve process improvements, reduce waste, and increase efficiency. Rooted in Lean principles and the Toyota Production System, standardized work provides a structured approach to documenting best practices and key elements of any process, ensuring smooth operation and consistent quality.

Challenges in implementing the Lean Six Sigma standard work need to be addressed with effective strategies.

In healthcare, for example, standardized work streamlines clinical workflows, reducing non-value-added activities and minimizing errors to improve patient outcomes. Teams utilize process maps and visual aids to identify bottlenecks and implement best practices, resulting in more efficient care delivery and enhanced patient safety.

Software development teams benefit from standardized work by establishing clear coding standards, testing protocols, and deployment procedures. This consistency accelerates delivery times, improves product quality, and enables teams to quickly identify and address issues, supporting a culture of continuous improvement.

When done correctly, Lean Six Sigma standard work can lead to significant reductions in waste and inefficiencies.

Service industries, such as finance and hospitality, leverage standardized work to ensure that every customer interaction meets defined quality standards. By documenting the key elements of customer service processes and training teams to follow them, organizations can deliver reliable, high-quality experiences that build customer loyalty.

Across all industries, the key to successful standardized work lies in identifying the most effective practices, documenting them clearly, and fostering a culture that encourages teams to improve processes continually. This approach not only reduces waste and increases efficiency but also enables organizations to adapt to changing customer needs and maintain a competitive edge.

Common Pitfalls and How to Avoid Them

“Set-and-Forget” Documentation

If version 1.2 of the sheet is still in use while engineering has just released version 1.3, the standard is already obsolete. Link document control to engineering change notices and drive a quarterly “red-tag audit” to purge outdated sheets.

Over-Standardization versus Flexibility

Maximizing the potential of Lean Six Sigma standard work is critical to achieving operational excellence.

Standardizing every micro-motion can backfire if customer mix or equipment varies. Protect only the key aspects that are critical to quality (CTQs); give operators kaizen cards to propose safer or faster alternatives. Approved suggestions immediately become the new standard, keeping creativity alive.

Change Fatigue and Engagement Drop-Off

Continuous improvement feels like continuous churn if wins are invisible. Celebrate each metric improved on the tier board for increased efficiency, share before-and-after videos, and rotate kaizen facilitation so every team member gets leadership experience.

Measuring Success: KPIs for Lean Six Sigma Standard Work

- Process Sigma Level & DPMO – a universal score for variation; strive for 4.0 σ or better in mixed-model environments.

- Overall Equipment Effectiveness (OEE) – multiplies availability, performance, and quality; correlates strongly with adherence to standard work.

- First-Pass Yield (FPY) and Rework Rates – the hidden factory that disappears when operators follow and improve the standard.

Plot each KPI on run charts; flag special-cause spikes for rapid root-cause analysis.

Integrating Lean Six Sigma standard work into an organization’s culture is crucial for sustaining performance improvement.

Technology Enablers: From Digital SOPs to AI-Driven Insights

Electronic Standard Work Instructions (e-SWIs)

Organizations that prioritize Lean Six Sigma standard work set themselves up for long-term success.

Cloud-hosted SOPs sync across tablets, smartwatches, and large kiosks. Barcode scans or RFID log-ins display only the latest approved revision for that SKU, eliminating “wrong version” mix-ups.

Augmented Reality for Operator Guidance

At Boeing, AR headsets overlay wiring diagrams directly onto fuselage panels, cutting inspection time by 2% and rework by 4%. Costly early prototypes are now succumbing to Moore’s Law, opening AR to mid-tier manufacturers.

Predictive Analytics for Proactive Quality

Machine-learning models forecast tool wear, ambient humidity impacts, or incoming material variability days ahead. When the model predicts a failure mode, it triggers a standard workge-perchangeoverlier tool changeover modified drying cycle—so defects never leave the station.

Ultimately, the concept of Lean Six Sigma standard work remains relevant across all industries.

By focusing on Lean Six Sigma standard work, companies can increase their overall effectiveness and efficiency.

By integrating Lean Six Sigma standard work into daily routines, companies can enhance their operational performance.

Future advancements in technology will influence how Lean Six Sigma standard work is implemented.

Integrating technology with Lean Six Sigma standard work can lead to more effective processes.

The Future of Lean Six Sigma Standard Work

Hyper-Automation and Citizen Developers

As organizations evolve, Lean Six Sigma standard work must adapt to meet new challenges.

Lean Six Sigma standard work serves as a framework for continuous improvement within organizations.

Low-code tools enable production supervisors to build their Kanban dashboards or Andon triggers in hours, not weeks. IT becomes a mentor rather than a bottleneck.

Sustainability and Green Manufacturing

Ultimately, Lean Six Sigma standard work is about creating value and ensuring quality in every process.

Emphasizing Lean Six Sigma standard work in training sessions can greatly enhance team capabilities.

The carbon footprint per unit is now displayed beside the takt time at daily huddles. Standards incorporate low-energy machine settings, recycling checkpoints, and efficient use of raw materials, aligning operational excellence with environmental, social, and governance (ESG) goals.

Workforce Upskilling in Industry 5.0

Cobots handle repetitive or ergonomic pain points, freeing human talent to focus on learning data analytics, root-cause facilitation, and cross-functional leadership—the very skills Lean Six Sigma needs to thrive in cyber-physical factories.

Conclusion and Next Steps

Standard work is not a static binder; it is a living agreement that aligns people, process, and customer value. Pair Lean waste removal with Six Sigma variation control, capture the best-known method, and audit it relentlessly. Start tomorrow: walk one process, record its actual cycle time, and post the first visual standard. Every improvement from that baseline will be faster, cheaper, and more sustainable—proof that operational excellence is a journey paved with disciplined steps.

Frequently Asked Questions

How often should standard work be updated?

Anytime a kaizen, engineering change, or VOC shift alters the CTQs, and at least quarterly via layered audits of the standard process.

Is standard work only for repetitive tasks?

No. Surgical teams, software deployment pipelines, and call-center scripts all rely on repeatable steps that can be standardized.

By prioritizing Lean Six Sigma standard work, businesses can ensure that they consistently meet customer needs.

Lean Six Sigma standard work will guide teams in their quest for excellence and customer satisfaction.

What if experienced operators refuse to follow the document?

Invite them to co-author the standard and make their expertise visible in the sheet. Shared ownership dissolves resistance.

Ensuring compliance with Lean Six Sigma standard work can significantly mitigate risks associated with operational failures.

Can digital SOPs fully replace paper?

Yes, provided every station has reliable hardware, offline fall-back, and strict revision control.

To enhance performance, companies should regularly review and refine their standard work processes using Lean Six Sigma principles.

Where should a small company start? Select the process that causes the most harm to customers. Map it, time-study it, draft a simple one-page standard, and check it daily. Lessons learned there will scale naturally.

Maintaining lean six sigma standard work practices can lead to higher operational efficiency and reduced costs.